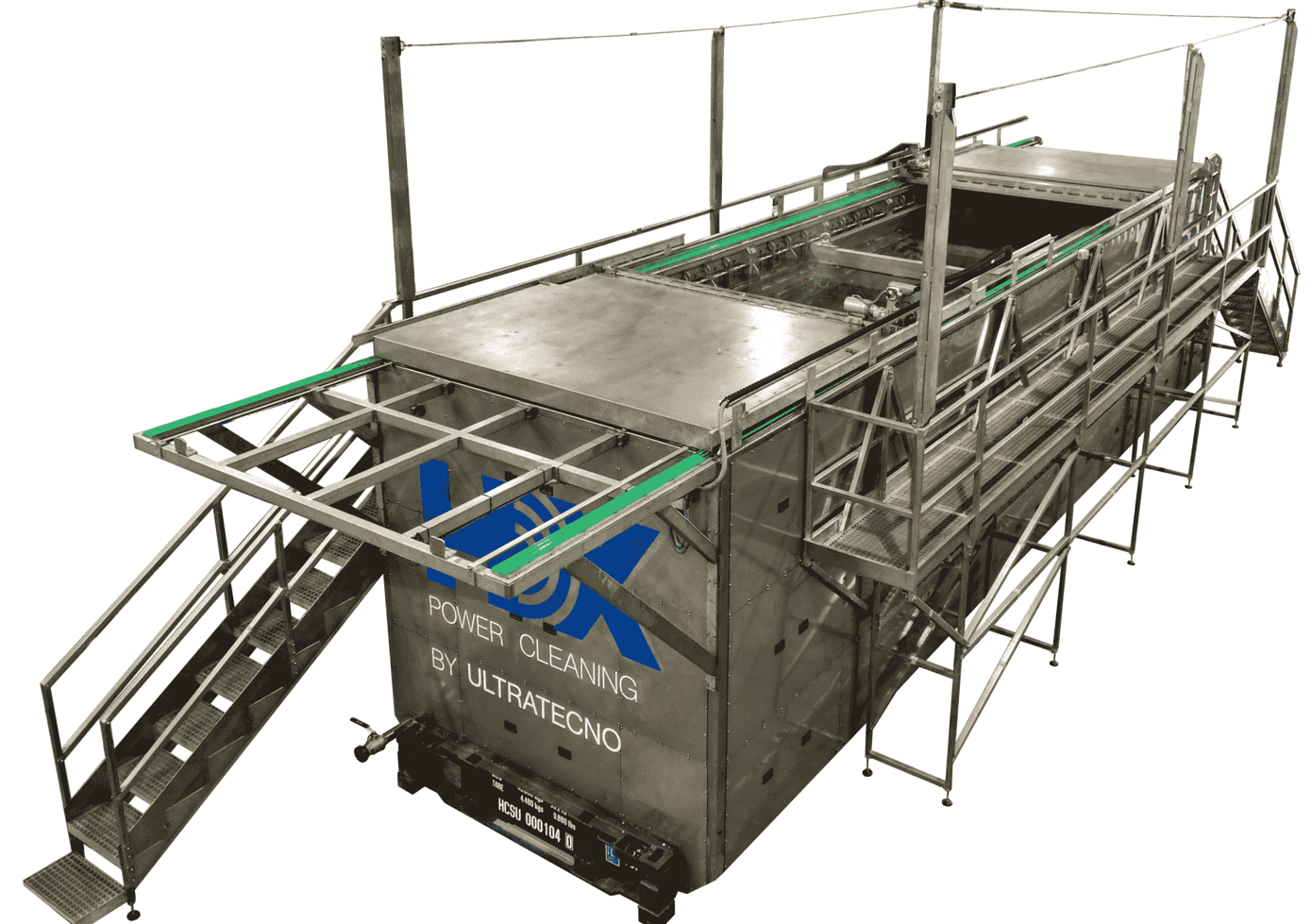

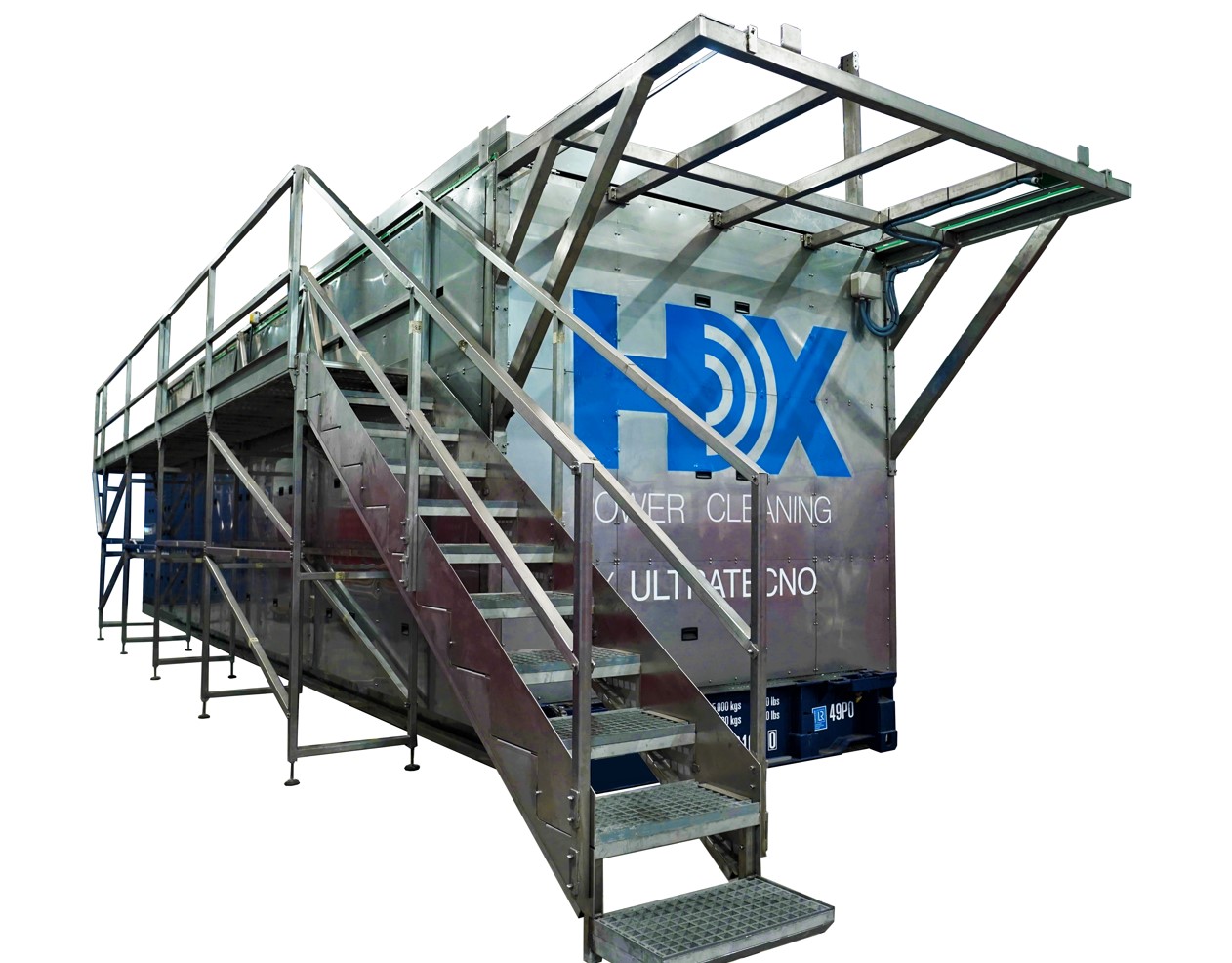

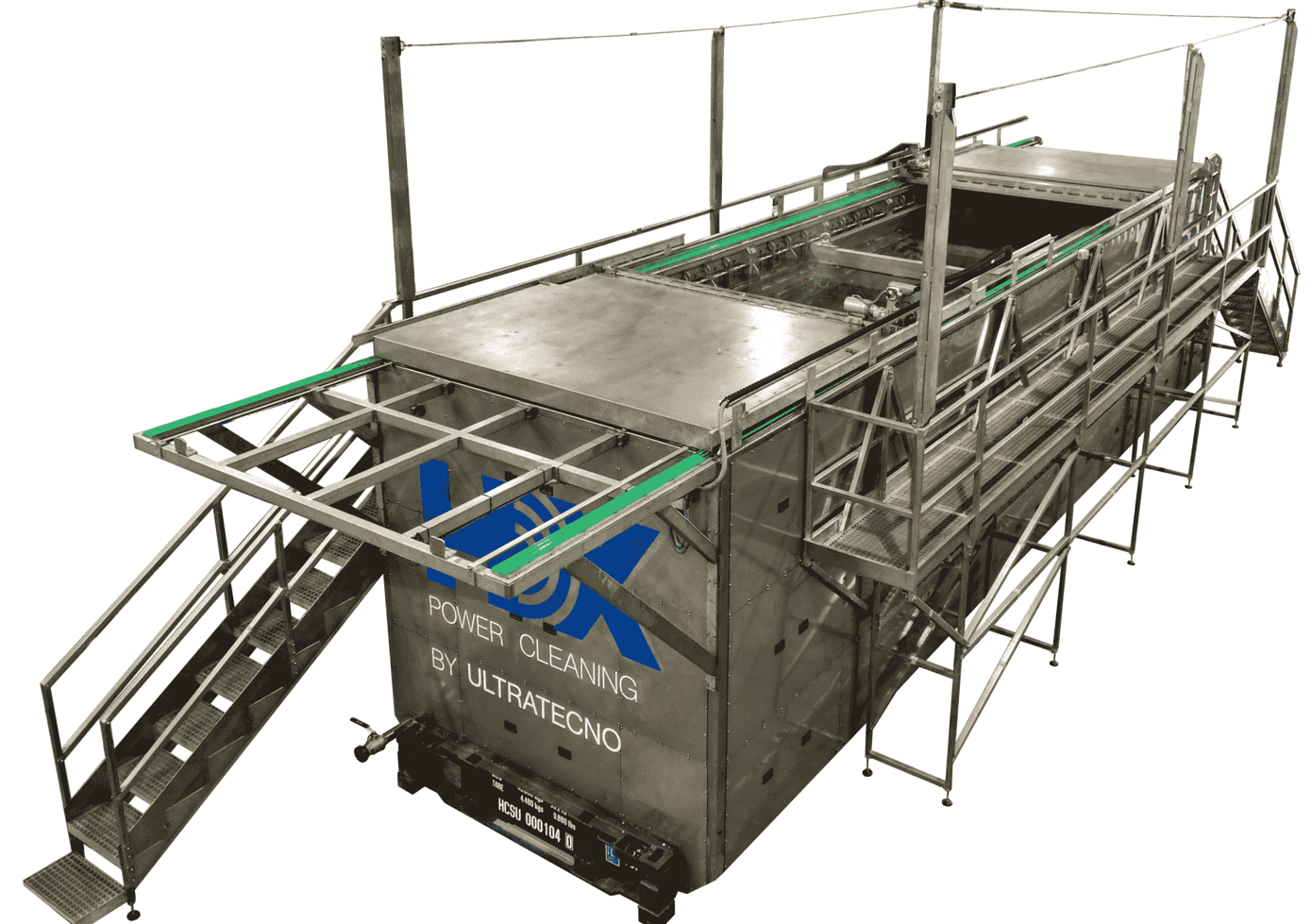

HX – HEAT EXCHANGER ULTRASONIC CLEANER

WE ARE A SPECIALIZED BRAND IN SELLING ULTRASONIC EQUIPMENT FOR CLEANING HEAT EXCHANGERS

HX Power Cleaning brand is specialized in selling ultrasonic cleaning heat exchanger machinery. HX Power Cleaning is supported by company Ultratecno, specialists in ultrasonic cleaning machinery for many types of applications with more than 50 years’ experience operating in the ultrasound world market.

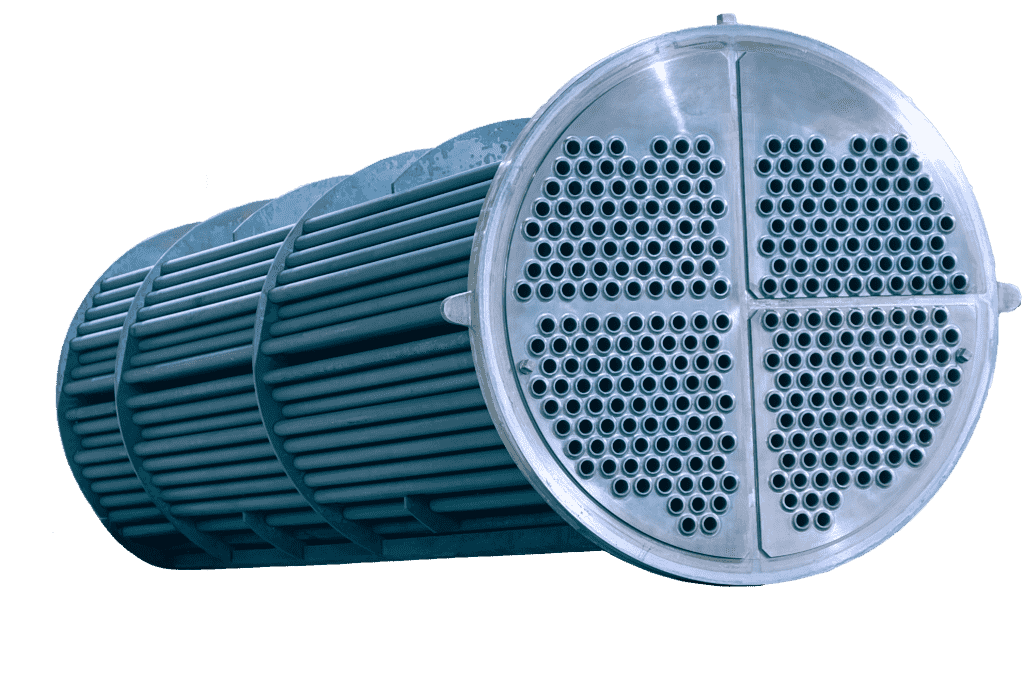

Ultratecno company is well known for being leader in manufacturing large ultrasonic cleaning tanks using a 28kHz frequency for difficult applications such as shell and tube heat exchanger maintenance in petrochemical, oil and gas industry.

The leaders in high-quality ultrasonic cleaning machines for heat exchangers for industrial cleaning services. HX currently distributes heat exchanger cleaner in Europe, Asia, Africa, America, and Oceania.

Make high-pressure water jetting method a thing of the past!

WHY CLEAN HEAT EXCHANGER WITH ULTRASOUND TECHNOLOGY?

Ultrasonic cleaning of heat exchangers and other components of heavy industrial require the use of best ultrasound technology.

You can find a wide range of methods and technologies and cleaning processes but none more efficient than our 28kHz frequency technology.

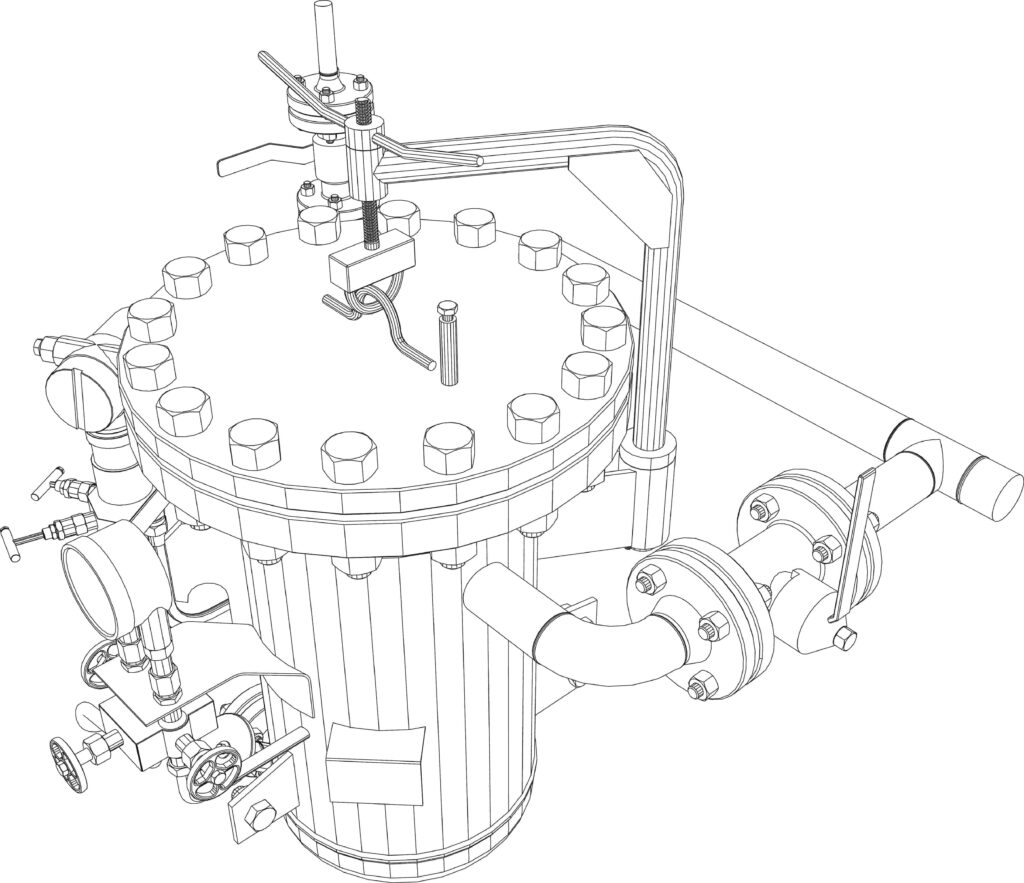

Your dirty pieces will be submerged in a large stainless steel water tank with a percentage of special detergent. In the tank, our transducers placed on walls will produce sound waves creating bobbles – cavitation process.

After this, dirt from you piece will begin to come loose obtaining a perfect cleaning result at the end of the process. It is necessary to rinse heat exchanger, in order to eliminate dirt from the extraction process.

If you need to clean a plate heat exchanger, HX is your solution for petrochemical industry.

CERTIFICATE OF QUALITY

ISO 9001 AUDITED ANNUALLY BY BUREAU VERITAS

WHAT ARE THE BENEFITS OF HEAT EXCHANGER TUBE CLEANING

WITH HX POWER ULTRASONIC TECHNOLOGY?

BEST PERFORMANCE ON THE MARKET

-

Ultrasonic Cleaning with powerful blasting effect from outside and inside parts provides excellent results, removing all dirt and returning part to bare metal and removing calcium carbonate deposits

-

Increases heat exchanger’s flow volume and heat transfer rate. Heat exchangers and parts are returned to service at 95% of original design performance. Ultrasonic stainless steel tanks perform twice as fast as hydro-blasting

-

Ensures perfect performance of heat transfer

-

Results only depend on machine, not operator

-

Ultrasound does not affect material and prevents damage caused by water pressure.

-

It is possible to clean different spare parts simultaneously

HUGE COST SAVINGS

-

Huge Labour Cost Savings as hydroblasting (high-demanding manpower) is reduced by 75% (only for rinsing)

-

Chemicals Savings as bath can be reused with up to 80 heat exchangers cleaned per bath preparation (with as many as 3 consecutive turnarounds with controlled climate storage up to 5 years). Achieving massive savings in Oil and Gas Industry.

-

Higher cleaning performance results in extended run time and double periods between turnarounds

-

Overall cleaning associated costs are reduced by 50% when compared to traditional hydroblasting

-

Reduce use of water and temperature control of hot water

-

Less contamination in the cleaning area

SAFETY

-

Hydro-blasting work is reduced by over 75% and only required for rinsing purposes, reducing associated risk

-

Reduces operators´ exposure to water treatment chemicals being an a non toxic method.

-

No transportation risks for large parts.

SUSTAINABILITY

-

66% Water consumption savings in comparison with hydroblasting (100.000 litres per unit)

-

66% reduced waste-water generation as baths are reused multiple times

-

10-15% reduced energy consumption & greenhouse gas emission

-

Increases recycling of old parts and reducing disposal cost

REQUIRE ANY FURTHER

INFORMATION CONCERNING

YOUR PROJECT?

FILL OUT THE FORM AND WE

WILL ASSESS YOUR REQUIREMENTS.